charpy impact test notch size|charpy impact test sample dimensions : Brand The standard Charpy impact test specimen is of dimension 55 mm × 10 mm × 10 mm, having a notch machined across one of the larger dimensions, as illustrated in Fig. 1.3. The Charpy . 无论您是为社交媒体还是大屏幕制作内容,全新的 VEGAS Pro 都是您唯一需要的视频编辑工具。在一个综合平台中编辑任何类型的材料、创建视频合成并添加动态图形。

{plog:ftitle_list}

鲨鱼瞄准镜. 发表于 四月 4, 2023 | 经过 行政. 在竞争激烈的在线扑克世界中, 获得超越对手的优势至关重要. 这就是Sharkscope, 在线扑克社区中强大的工具, 发挥作用. 被誉为最全面的单桌和多桌扑克锦标赛统计在线数据库, Sharkscope 成为扑克爱好者不可或缺的 .

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .The standard Charpy impact test specimen is of dimension 55 mm × 10 mm × 10 mm, having a notch machined across one of the larger dimensions, as illustrated in Fig. 1.3. The Charpy .

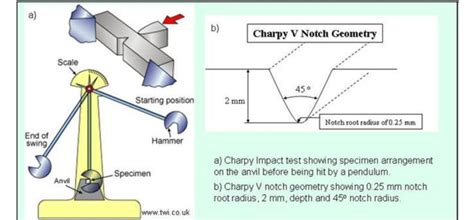

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure . The Charpy Impact Test, also known as a V-notch test, evaluates a material’s impact strength by measuring the energy required to fracture a standardized sample with a machined V-notch. Using a released pendulum, . The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to fracture a pre-prepared and standardized .

charpy v notch toughness

charpy v notch testing standard

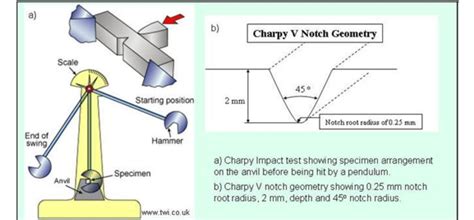

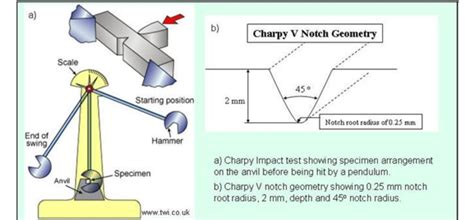

1. Notch test specimens. The standard size of a specimen for Charpy impact testing is 10 mm × 10 mm × 55 mm. A 2mm deep notch with an angle of 45° and a tip radius of 0.25mm is then machined into one face of the .

4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specifications In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm. The notch in the middle has a V .

charpy v notch testing requirements

ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the . Charpy impact test is a comparative style test used to define a material’s impact strength. Learn more about it here. . There are multiple standards used. However, in general, the sample size is 55 x 10 x 10 mm with .Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. . Specimen size: Specimens are 80 x 10mm by thickness. The specimens can be either notched or unnotched .In addition to softening behavior, the resistance to notch sensitivity (ductility) of FQZ is also investigated via the Charpy impact testing. Fig. 23 shows the specimen dimension and notch schematic diagram of Charpy V notch (CVN) test [21]. Small-sized CVN specimens are prepared from 6-mm-thick TIG welded RDE40 and AA7018 alloys.

charpy v notch test procedure

The Charpy test results are affected by many factors, such as the state of the specimen (size, notch type, notch depth, etc.), the state of the impact testing machine (stiffness, hammer radius . Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . • U-notch or keyhole notch – A 5mm deep notch with 1mm radius at the base of the notch. What Does the Charpy Test Involve?The Charpy impact and notched impact test to ISO 179-1 and ISO 179-2 provide characteristic values for impact strength at high strain rates in the form of an area-related energy value. The tests are normally performed in normal climate or at low temperatures. Applications include: The comparison of different molding materials PDF | Description Presents worldwide research on the factors and variables of the Charpy test. Consists of 12 papers in sections on The Pendulum-Impact. | Find, read and cite all the research .

5.3 For this test method, the energy lost by the pendulum during the breakage of the specimen is the sum of the energies required to initiate fracture of the specimen; to propagate the fracture across the specimen; to throw the free ends of the broken specimen (toss energy); to bend the specimen; to produce vibration in the pendulum arm; to produce vibration or .Here’s how the process works: The test specimen, typically 55 mm long and 10 mm square with a 2 mm deep V-notch, is positioned horizontally in the Charpy impact testing machine. The Charpy impact test specimen notch faces away from the pendulum, which swings down from a set height to strike the sample.the production of reference Charpy specimens for the indirect verification of impact testing machines in accordance with ASTM E23-12c: two quenched and tempered 4340 steels (with different mechanical properties . • sub-size Charpy V-notch specimens (SCVN) with thicknesses B = 7.5 mm (3/4-size), 5 mm (1/2-size), and 2.5

Charpy Impact Testing Sub-Size Specimens to ASTM E23, A370 and ISO 148-1. ASTM E23 and ISO 148-1 define test methods for Charpy impact testing of notched-bar metallic specimens. ASTM A370 also includes Charpy impact test method requirements but focuses only on steel products. All three standards provide details for properly measuring the energy . Four types of impact testing are described in detail below, encompassing the pendulum, drop-weight, and dynamic tear methods: 1. Charpy. The Charpy impact test, also known as the V-notch test, is a type of impact test where a weighted pendulum hammer is released from a specified height and strikes the part. A Charpy impact testing apparatus, a .

charpy v notch sample size

Test methods used to measure Notched Izod Impact (or notch sensitivity) and Charpy Impact in plastics are: ASTM D256-10(2018) : Plastics — Determination of Izod pendulum impact resistance ISO 180:2019 : Plastics — Determination of Izod impact strength

nasa tools measure thick icecaps

4.3 The Charpy V-notch impact test in relation to other tests. 4.4 Factors influencing impact properties. 4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specifications. 5 Information to be gained from the impact test. 6 Subsize test pieces. The “standard” notch used in the Charpy impact test is the 2 mm deep V-notch with a 0.25 mm root radius, but other geometries are or have been sometimes used. Depending on notch geometry, the test is known as the Charpy-V impact test (CVN) or Charpy-U impact test (CUN) or even Charpy-keyhole. The U-notch has normally a radius of 1 mm.

A phenomenological model of the transition has been developed in which the Charpy V-notch impact energy is expressed as a function of carbon content and temperature. . (2004) 373–386 Material inertia and size effects in the .

native oxide thickness measurement

This puts the side with the notch into tension, causing an initiation of fracture from the notch. Figure 2 Charpy Test Specimen under Load. The most commonly used specimen, the Charpy V-notch (CVN), is 10 × 10 × 55 mm and has a V-notch 2 mm deep with a 0.25 mm tip radius.• ISO 180: Plastics – Determination of Izod Impact Strength of Rigid Materials. CHARPY IMPACT TESTING IZOD IMPACT TESTING Tested Materials Plastics Plastics Types of Notches (0.25mm) Preferred V-notch V-notch Specimen Position Horizontally, Notch facing away from the pendulum Vertically, Notch facing towards the pendulumadjustment of sub-size Charpy-V specimen . KV/(Bb) [J/cm. 2] T [o. C] McNicol 1965. McNicol, R. (1965, September). Correlation of Charpy Test Results for Standard and Nonstandard Size Specimens. Welding Research Supplement, pp. 385-393. . Impact Characterization of Line Pipe Steels by Means of Standard, Sub-Size and Miniaturized Charpy .

For steel products with section thicknesses of about 10mm or less that are required to be impact tested, it is necessary to use Charpy V-notch test specimens that are smaller than the standard 10mm x 10mm test specimens (sub-size specimens).

ISO 148-1 U-Notch pendulum testing is the European standard equivalent to ASTM E23 Charpy Impact testing.Both specimens use 10mm x 10mm x 55 mm specimens. Where the 45° V notch is required in the ASTM specification, it is replaced by 2mm or 5mm deep U notch geometry in the ISO specification.The stress concentration is less severe and has been found to be similar .Issues related to the size dependence of the upper shelf energy (USE) and the ductile-to-brittle transition temperature (DBTT) in the Charpy V-notch test are investigated. Emphasis is placed on the interplay between inertial, strain rate hardening, strain hardening, thermal softening and material length scale effects. Geometrically similar specimens are considered first. For such .Conference: Specimen size effects in Charpy impact testing . Conference: Symposium on Charpy impact test: factors and variables, Orlando, FL (USA), 8-9 Nov 1989 Country of Publication: United States Language: . On impact testing .Charpy impact testing determines notch toughness, temperature-dependent ductile-brittle transition rate, and ductility of a material. . According to ASTM A370, [12] the standard specimen size for Charpy impact testing is 10 mm × 10 mm × 55 mm. Request a Quote. PHYSICAL TESTING LAB SERVICES. Abrasion (Taber) Adhesion (Peel) Testing

In order to develop the small specimen technology in Charpy impact testing, the effects of V-notch dimensions on the test results were investigated for miniaturized specimens of a ferritic steel, Japanese Ferrite/Martensite Dual Phase Steel (JFMS). The miniaturized Charpy specimens had four different square cross-sections of 3.3, 2, 1.5 and 1 mm, and each of them had a . The Charpy Impact Test, also known as the Charpy V-notch test, is a crucial method in the field of materials testing. This test helps determine a material’s ability to absorb energy and resist breakage under high-velocity impacts. . Specimen Size: The standard dimensions for test specimens are usually 55 mm x 10 mm x 10 mm, though sub-size .

ndc thickness measurement

nickel coating thickness measurement

web14 de ago. de 2019 · 纵观 Rules of the Internet 这些规则,绝大部分规则都是对于 4chan 论坛现状的描写,本来也只是 4chan 用户们的自娱自乐,不会有很大的流传度。直到「 互联网规则第 34 条 」,the Rule 34 出现了。Rule 34 的内容是:There is porn of it, no exceptions.

charpy impact test notch size|charpy impact test sample dimensions